Going robotic

Roboticizing a $2 trillion industry

In today’s Diary:

The dirty secret behind humanoid demos

Excavators get Waymo’d

The Waymo Mafia

ChatGPT for robots

Soon to be the most valuable robotics company in America?

Dear Rational Optimist,

You won’t believe what I bought here in Abu Dhabi!

A robot that washes my dirty dishes. Look…

Okay, it’s just a dishwasher. But it’s the first one I’ve owned. My kids love it. We load it together, press start, and then we’re building Legos instead of scrubbing forks.

When I say “robot,” you might imagine the Jetsons’ Rosey housekeeping robot gliding through our living rooms, vacuuming and pouring cocktails. We’ll be waiting a while for humanoid robots like that.

But don’t let that distract you from the real opportunity here. Right now, several multi-trillion-dollar industries are going robotic… many of them on the back of small startups. Let’s meet them.

What do you call a robot that drives?

A Waymo.

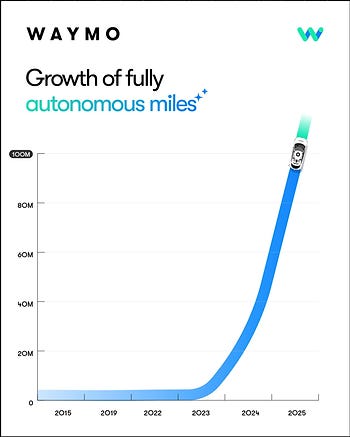

Waymo’s robotaxis have now clocked 100 million fully autonomous miles. Like most big shifts it happened gradually… then suddenly.

I’ve ridden in Waymos in Austin, LA, and San Francisco. If you’re a non-believer, go take a Waymo ride. It’ll change your mind, I guarantee it. Or try Tesla’s Full Self-Driving mode.

Notice that robotaxis do one job beautifully: Drive. And they do it better than most humans.

Now copy and paste this to other industries. That’s the model for our imminent future.

Bearish on humanoids (for now).

In 2004 DARPA kick-started the self-driving car industry with a desert race. Every car failed. It took another 20 years for Waymo to ditch the safety drivers and become ready for full deployment.

Recently, a robot “half-marathon” took place in Beijing. Twenty-one robot runners lined up; engineers were allowed to pick them up if they fell over and swap batteries mid-race.

Even with that help, only six crossed the finish line.

Do you see the parallel? Humanoids are in their DARPA-desert stage. They’re 10-20 years behind self-driving cars.

I know, the humanoid demos look amazing. Figure’s robot smoothly placing fruit in the fridge. China’s Unitree robot flipping like Bruce Lee. 1X’s Neo watering plants and folding laundry in a TED Talk.

The dirty secret is most of these demos are tightly staged or teleoperated by humans behind the curtain. Like the Wizard of Oz.

Remember Tesla’s flashy launch of its Optimus robots pouring beers? Those robo-bartenders were controlled by a nearby human.

1X openly admits many of Neo’s household tasks rely on remote operators guiding its hands with VR joysticks. Beware the flashy demo.

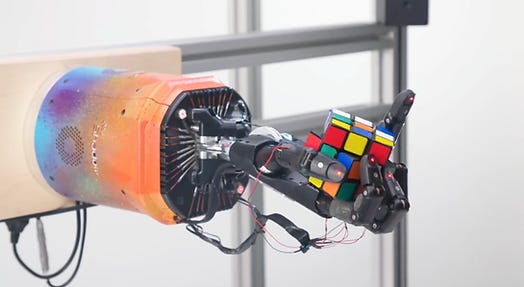

This is one more reason I seek insight from actual experts – meeting them in person whenever I can. Like OpenAI’s former Chief Research Officer Bob McGrew, whom I met in San Francisco a few months back.

Bob led the OpenAI team that taught a robot hand to solve a Rubik’s Cube. Imagine the joy when the four sides lined up!

Over coffee Bob told me, “Manipulation is the hard problem we need to solve to make humanoid robots useful.”

In robotics, hard things are easy and easy things are hard. A humanoid robot can do a backflip. But ask it to unwrap a Band-Aid or fold laundry, and it’s useless. Even the “best” humanoids have the dexterity of my 9-month-old son.

A robotics innovator will eventually figure out manipulation. But it took 20 years to ramp up robotaxis, and it’ll likely take just as long for humanoids.

Boston Dynamics proves the point. Its humanoid, Atlas, is a YouTube celebrity. But it makes no money. All the company’s revenues come from a box-unloading arm on wheels and a four-legged inspection bot.

Nvidia founder Jensen Huang says, “Most things that move will be robotic.” I agree. But they won’t look like you and me. The future of robotics will be specialized.

A funny thing happened in Detroit this summer…

I was listening to our friend

’s American Optimist podcast with Boris Sofman, a former senior engineer at Waymo.Then I looked up from my phone, and Boris was standing right in front of me! He was at the Reindustrialize summit talking about his new venture, Bedrock Robotics.

Bedrock will do for excavators what Waymo did for cars: make them autonomous.

Bedrock isn’t building new bulldozers. Instead, it makes a box with cameras, LiDAR (remote sensing tech) and a computer that bolts onto any ordinary excavator or digger. It transforms a regular digger into a robo-digger capable of working through the night, in blistering heat, without breaks.

Bedrock has already moved hundreds of thousands of cubic meters of dirt in tests in Arizona and Texas.

Innovators like Bedrock will help America defeat The Blight by building stuff faster and cheaper. Bedrock’s goal is to cut earth-moving costs by at least 20% and pull schedules forward by months.

I think Bedrock will be wildly successful. It’s not trying to convince builders to buy some fancy new machine. That’s hard. It’s making their existing excavators and diggers smarter. That’s easy, which means fast adoption.

Bedrock feels inevitable. In a decade we’ll talk about it the way we talk about Waymo today.

It also fits my robot thesis:

Specialists win first.

Bedrock gives an excavator a digital brain, turning it into a specialist robot that does one gnarly job reliably, all day.

Construction is a $2 trillion industry in the US alone, yet it’s one of the least automated. Projects often require moving dozens of Olympic swimming pool-sized mounds of dirt before anything gets built.

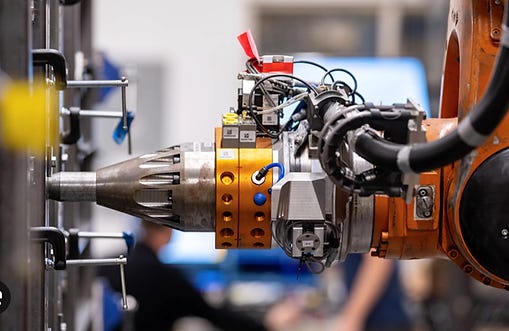

Meanwhile, in Chatsworth, California two robot arms are busy shaping steel the way a potter shapes clay.

Meet the robo-blacksmith.

Machina Labs’ two huge robot arms press on opposite sides of a sheet of metal. By pinching, rolling and nudging small spots they can gradually shape it into anything.

With this process – called “robo-forming” – Machina Labs is reinventing how we make sheet-metal parts. This is a $250 billion industry. It’s the backbone of the things we drive, sit in, or fly on.

Today most sheet-metal parts are made with stamping dies. These giant molds cost millions of dollars and take months to make. This puts a straitjacket on innovation.

Robo-forming eliminates the need for factories full of specialized tools, meaning one factory could make Jeeps in the morning and jumbo jets in the afternoon.

When I chatted with Machina founder Ed Mehr on the phone this week, he told me the goal is to make “building real stuff in the physical world as agile and easy as writing code.”

Machina has already delivered parts for NASA and the Department of Defense, including a donut-shaped fuel tank.

Its new system is portable, too. You can truck it in and put a “pop-up factory” wherever you need one.

Software will eat manufacturing.

Machina’s big breakthrough wasn’t designing a better robot arm. In fact, is uses off-the-shelf arms from KUKA and other companies.

What Machina pioneered was a software “brain” allowing two robots to sync up and press metal with enough force to crush a truck.

Robots are hardware. Metal and steel. But making them useful is a software problem.

Tesla proves this. It’s self-driving tech improved 100X in 2024, measured by how often humans needed to take the wheel. The physical car didn’t change. Better software enabled the leap.

We can now “update” software-powered robots (like Teslas) as easily as our iPhones. Update the model, push an over-the-air release, and every robot in the fleet gets smarter overnight. Blows my mind!

I’m so bullish on software-first robotics. Waymo’s cars learn from the whole fleet. Machina Labs turns “dumb” robot arms into a self-improving system.

The most successful robotics companies today, be it Waymo or Matic’s robo-vacuums, are really…

Software companies wearing hard hats.

Physical Intelligence is building an AI system that can plug into many different types of robots and help them learn.

Think of it like an operating system for the physical world. Just as Android runs on Samsung and Google phones, PI’s models will run on robot arms, vacuums and warehouse unloaders.

It’s like ChatGPT for robots. The model absorbs what the robot sees, what it reads or hears, and what it knows about itself. Am I a vacuum or an arm?

Then it spits out commands that tell the robotic grippers, wrists, and fingers exactly how to move. You can prompt it with commands like “clean the kitchen” and it breaks that into steps. Pick up the cup, wipe the counter, put things away… Then it executes those steps one by one.

Physical Intelligence is training its AI “brain” to operate across many different robots. In demos the model could fold a crumpled shirt from a laundry basket, a longtime “impossible” benchmark. It also sorted dishes from trash on a table and built a box while correcting itself mid-task.

I think Physical Intelligence nails the winning strategy: armies of specialist robots powered by a generalist brain.

Bob McGrew told me he’s “impressed by Physical intelligence.” That’s how you know it’s one to watch. Physical Intelligence could one day be the most valuable robotics company in America.

Will robotics get its ChatGPT moment?

A single “WOW” event that flips the world overnight?

Probably not.

Robotics will expand through a thousand little wow moments.

Here’s your cheat sheet for the near future of robotics:

Don’t get hypnotized by humanoid backflips. They’re cool demos, but the useful stuff looks boring: parcel sorters, robo-diggers and warehouse unloaders. That’s where money is already being made.

Remember, specialists win first.

Follow the software. Waymo isn’t winning the robotaxi race because it had the best car. It won because it has the best brain. Follow companies building AI software for robotics.

Watch China. It’s already deployed more than half of all new industrial robots in the world. They’re running “lights-out” factories without humans (yes, the lights are literally off). America can’t afford to sleep on this.

For my entrepreneurial friends interested in robotics, pick a verb and own it. Drive. Dig. Inspect. Fold. Pick. Place. Build a robot that does one job beautifully.

If you’re an investor, you now know a secret. The legacy robotics companies like ABB, Fanuc and Yaskawa are toast in this new world of physical AI.

Picture 2030…

Drones zip between rooftops, crisscrossing your city’s skyline.

At night, quiet vans with spinning LiDARs prowl the streets, moving goods while you sleep.

At the edge of town, warehouses hum with arms and mobile shelves, while robo-unloaders crawl into trailers like giant spiders.

In hospitals, white cylinders the size of dorm fridges deliver meds to patients.

Welcome to the robo-future. It’s run by armies of specialists and powered by shared AI brains, transforming how we build, move, and live.

I encourage you to try this stuff out. Ride in a robotaxi. Get a drone to deliver your lunch. Visit an Amazon warehouse and watch its army of robots in action.

Then tell me how it goes in the comments below.

And click those “Like” and “Restack” buttons to help us spread the word. We need more rational optimists!

—Stephen McBride

Stephen McBride is a co-founder of the Rational Optimist Society.

My husband and I recently used our newest Tesla Y with full self driving to travel from the East Coast to the Rockies then North through three Canadian provinces and back to North Carolina. It was the most enjoyable trip we’ve made because the car drove us everywhere we wanted to go. We are Senior citizens and enjoyed not having to control the car except for a very few times, mostly through temporary road construction sites. This is the future of driving and it is much safer and smoother driving than even we can drive as humans. Our grandchildren were amazed by the car’s self driving capabilities. This is the best future for safe road travel!

35 years ago an engineer at ABB robotics said the human hand and wrist has 31 degrees of freedom. This is the biggest challenge to robots end effectors. Yes AI can help but we humans are a magical machine not easily replicated.